Belt Joint Machine (Belt Splicing Machine)

Belt Joint Machine (Belt Splicing Machine)

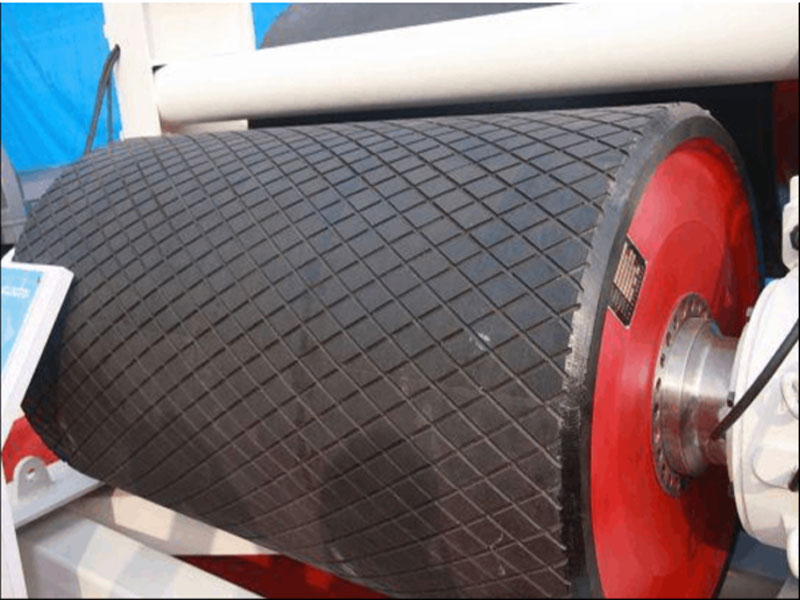

A Belt Joint Machine, also known as a belt splicing machine or belt vulcanizing press, is a specialized piece of equipment used to create a strong, durable, and seamless joint (or splice) in conveyor belts, transmission belts, or other types of industrial belts. This process is crucial for installing new belts, repairing damaged ones, or joining belt ends to form a continuous loop.

WhatsApp: +8618764293079

Email: mwinbelt@qdmwingroup.com

Product Description

Belt Joint Machine (Belt Splicing Machine)

A Belt Joint Machine, also known as a belt splicing machine or belt vulcanizing press, is a specialized piece of equipment used to create a strong, durable, and seamless joint (or splice) in conveyor belts, transmission belts, or other types of industrial belts. This process is crucial for installing new belts, repairing damaged ones, or joining belt ends to form a continuous loop.

Core Functions:

1. Joining/Splicing: Its primary purpose is to permanently connect two ends of a belt.

2. Repairing: It can be used to repair rips, tears, or damaged sections by vulcanizing a patch or creating a new splice.

Main Types & Processes:

There are two fundamental splicing methods, each requiring specific machines:

Hot (Thermal) Vulcanizing Splice: This is the most common and robust method for conveyor belts.

Machine: A Vulcanizing Press applies precise, even heat and pressure to the splice area.

Process: The belt ends are cut and prepared in a stepped or finger pattern. A layer of uncured rubber (skimming) is applied. The joint is placed between the heated platens of the press. Under controlled temperature and pressure, the rubber cures (vulcanizes), chemically bonding the ends into a single, homogeneous piece that is often as strong as the original belt.

Result: A seamless, flexible, and long-lasting joint ideal for heavy-duty applications.

Cold Splice: Uses chemical bonding without external heat.

Machine: A Cold Splicing Press or clamping device applies pressure.

Process: The belt ends are prepared and coated with a special high-strength adhesive (cement). The joint is clamped under pressure for a set curing time until the adhesive sets.

Result: A strong joint suitable for lighter-duty belts or situations where a vulcanizer is impractical. It is generally faster but may be less durable than a hot splice in demanding conditions.

Key Components of a Typical Hot Vulcanizing Machine:

Heating Platens: Electrically or steam-heated metal plates that apply uniform heat.

Pressure System: Hydraulic jacks or manual bolts that apply consistent pressure across the joint.

Control Unit: Regulates and monitors temperature, pressure, and time.

Frame/Structure: A rigid frame (often aluminum for portability) that holds the platens and withstands clamping force.

Main Applications:

Mining: Joining high-tension, steel-cord or fabric-reinforced conveyor belts.

Ports & Terminals: Maintaining ship-loading and bulk material handling systems.

Cement & Steel Plants: Splicing belts in high-heat and abrasive environments.

Power Plants: For coal and biomass handling conveyor belts.

Aggregate and Quarrying: Repairing belts carrying rock and sand.

Package Handling: For lighter conveyor systems in logistics.

Advantages of Using a Professional Belt Joint Machine:

Strength & Reliability: Creates a joint with high efficiency (often 90-95% of original belt strength).

Smoothness: Produces a smooth, aligned joint that minimizes wear, vibration, and spillage.

Durability: Resists material ingress and withstands the belt’s operational stresses (tension, flexing, impact).

Longevity: Extends the overall service life of the conveyor belt system.

In summary, a Belt Joint Machine is an essential tool in industrial maintenance, ensuring the integrity, safety, and efficiency of continuous material handling systems by creating high-performance, permanent bonds in conveyor belts.

Tell Us What You're Looking For.

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!

Tell Us What You're Looking For.

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!