Chevron Pattern Conveyor Belts

Chevron Pattern Conveyor Belts

Patterned conveyor belts, also known as profiled or textured conveyor belts, are a specialized type of conveying system designed with raised patterns or profiles on their surface. These patterns enhance the belt's functionality in various material handling applications by improving grip, increasing incline capabilities, and preventing material slippage.

WhatsApp: +8618764293079

Email: mwinbelt@qdmwingroup.com

Product Description

Chevron Pattern Conveyor Belts

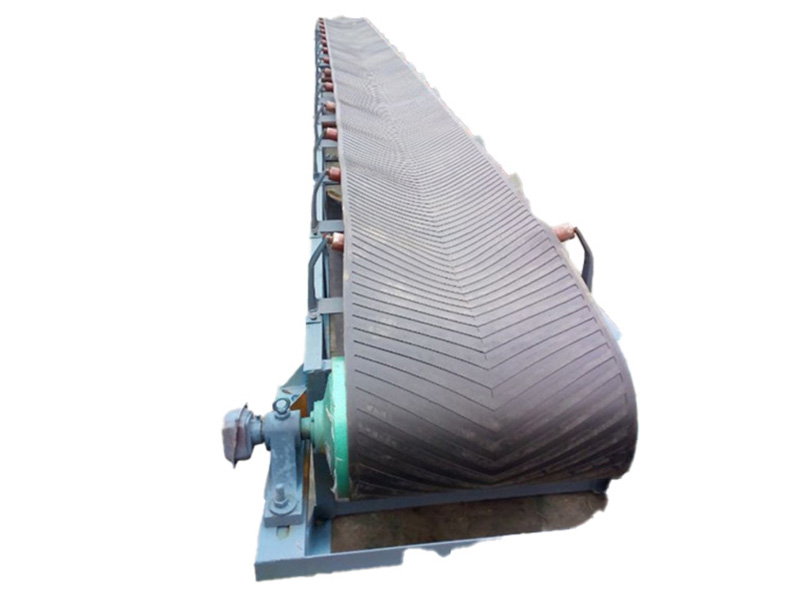

Patterned conveyor belts, also known as profiled or textured conveyor belts, are a specialized type of conveying system designed with raised patterns or profiles on their surface. These patterns enhance the belt’s functionality in various material handling applications by improving grip, increasing incline capabilities, and preventing material slippage.

Common Pattern Types:

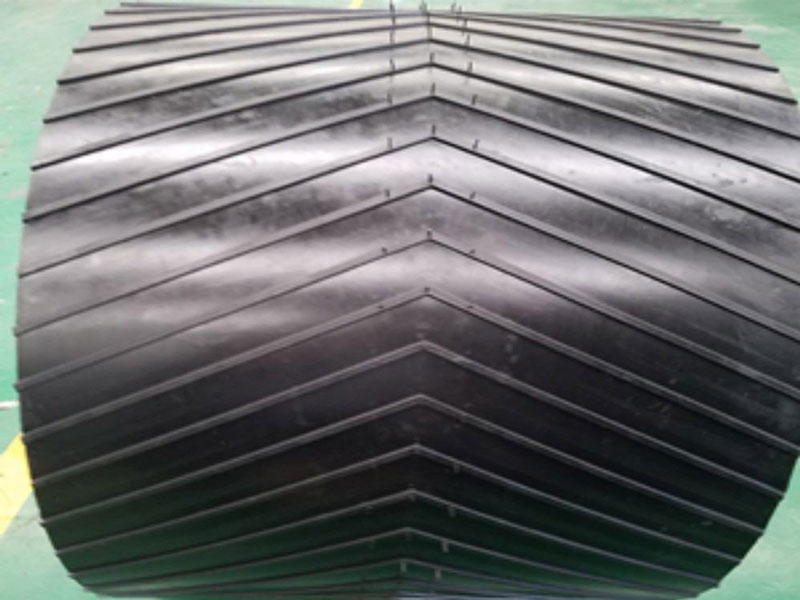

1. Herringbone Pattern: Features V-shaped ribs angled in the direction of travel, ideal for inclines and preventing load rollback.

2. Diamond Pattern: Provides excellent grip and stability, suitable for packaging, boxing, and transporting bags.

3. Chevron Pattern: Similar to herringbone but with continuous ridges, effective for loose or granular materials on slopes.

4. Ribbed Pattern (Transverse Ribs): Includes straight, raised ribs perpendicular to travel, used for lightweight item transport.

5. Cleat Pattern: Features raised barriers (cleats) to create compartments, perfect for steep inclines or loose bulk materials.

6. Nubs or Studs: Small, evenly spaced protrusions for gentle handling of delicate items like fruits or electronics.

Key Features and Benefits:

- – Increased Friction: Prevents materials from sliding during transport.

- – High Incline Capability: Enables efficient conveying at angles up to 30-40 degrees.

- – Material Stability: Reduces spillage and waste.

- – Versatility: Suitable for diverse industries and environments.

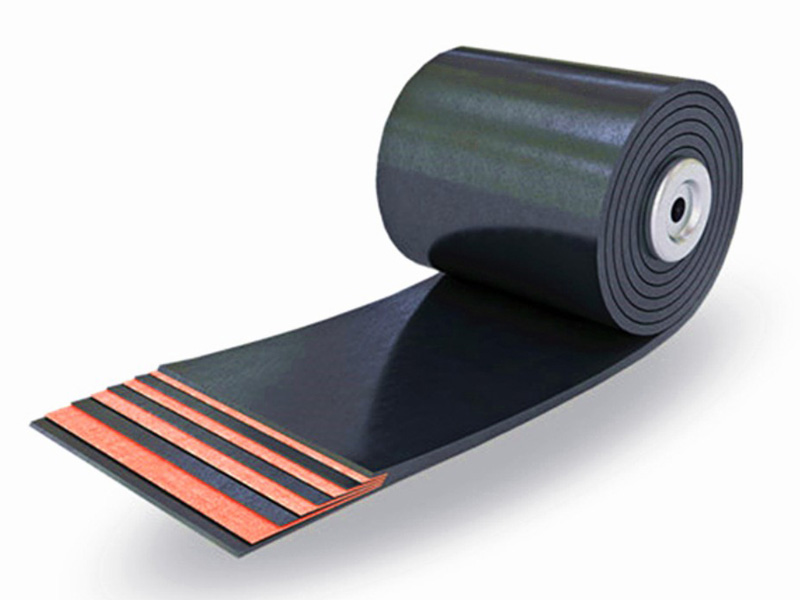

- – Durability: Often made from robust materials like rubber, PVC, or PU.

Typical Applications:

- – Agriculture (grain, seeds, produce)

- – Mining and quarrying (coal, aggregates)

- – Food processing

- – Packaging and logistics

- – Construction and manufacturing

Patterned conveyor belts are essential solutions for challenging conveying tasks where standard flat belts are ineffective. Their design ensures reliable, efficient, and safe transport of materials across various industrial sectors.

Product Specifications

1. Pattern Rubber Conveyor Belt Specification:

| Belt Type | Fabric type | Fabric Thickness | Rubber Cover Thickness | Width (mm) | Length (M) | |

| Top(mm) | Bottom(mm) | |||||

| EP Belt | EP-100 | 0.75 | 2-8 | 0-5 | 400-2500 | <=300 |

| EP-150 | 0.85 | |||||

| EP-200 | 0.90 | 500-2500 | ||||

| EP-250 | 1.15 | |||||

| EP-300 | 1.25 | |||||

| EP-400 | 1.45 | 600-2500 | ||||

| EP-500 | 1.55 | |||||

| Belt Type | Fabric type | Fabric Thickness | Rubber Cover Thickness | Width (mm) | Length (M) | |

| Top(mm) | Bottom(mm) | |||||

| NN Belt | NN-100 | 0.75 | 2.5-8 | 0-5.5 | 400-2500 | <=300 |

| NN-150 | 0.8 | |||||

| NN-200 | 0.9 | 500-2500 | ||||

| NN-250 | 1.15 | |||||

| NN-300 | 1.25 | |||||

| NN-400 | 1.45 | 800-2500 | ||||

| NN-500 | 1.55 | |||||

2. Pattern Rubber Conveyor Belt Standard:

| Rubber Cover Grade | Tensile Strength (Mpa) | Elongation at break (%) | Abrasion (mm3) |

| H | 24.0 | 450 | 120 |

| D | 18.0 | 400 | 100 |

| L | 15.0 | 350 | 200 |

| Standards | Cover Rubber | Adhesion | ||||

| Tensile Strength | Elongation at break | Abrasion | Cover to Ply | Cover to Ply | Ply to Ply | |

| DIN22102 | Mpa | % | mm3 | N/mm (≤1.5mm) |

N/mm (>1.5mm) |

N/mm |

| DIN 22102-Z | 15 | 350 | 250 | 3.5 | 4.5 | 5 |

| DIN 22102-W | 18 | 400 | 90 | 3.5 | 4.5 | 5 |

| DIN 22102-Y | 20 | 400 | 150 | 3.5 | 4.5 | 5 |

| DIN 22102-X | 25 | 450 | 120 | 3.5 | 4.5 | 5 |

| Standards | Cover Rubber | Adhesion | ||||

| Tensile Strength | Elongation at break | Abrasion | Cover to Ply | Cover to Ply | Ply to Ply | |

| AS 1332 | Mpa | % | mm3 | N/mm (≤1.9mm) |

N/mm (>1.9mm) |

N/mm |

| AS 1332-N17 | 17 | 400 | 200 | 4 | 4.8 | 6 |

| AS 1332-M24 | 24 | 450 | 125 | 4 | 4.8 | 6 |

We also could offer belt with cover grade in accordance to International standard such as DIN 22102, RMA, AS 1332, SABS 1173/2000, IS 1891, BS 490, JIS K 6322, etc.

Tell Us What You're Looking For.

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!

Tell Us What You're Looking For.

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!