Rubber Vulcanizing Press Machine

Rubber Vulcanizing Press Machine

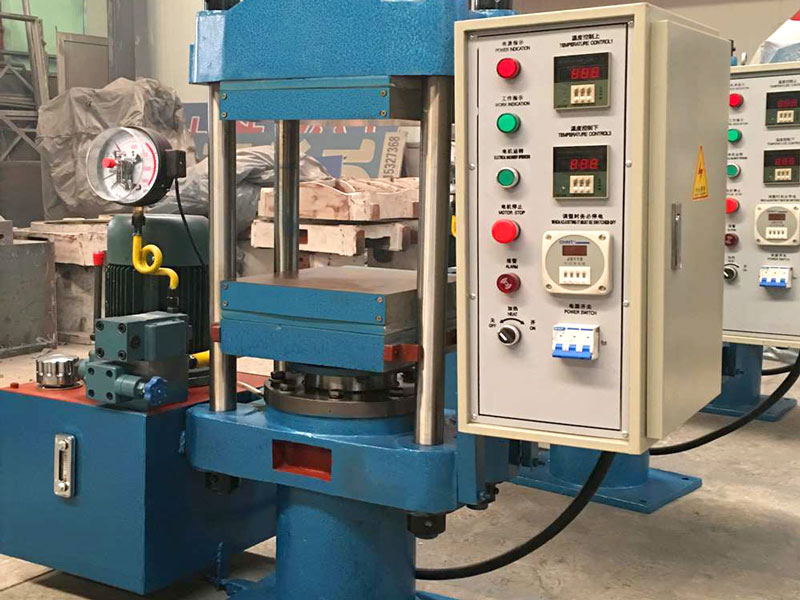

A flat vulcanizing press, also commonly known as a slab vulcanizer, platen press, or compression molding press, is a fundamental and widely used machine in the rubber and plastics industries for the curing (vulcanization) and molding of materials. Its primary function is to apply precise heat and pressure to raw rubber compounds or other thermosetting polymers, transforming them into durable, elastic, and final-shaped products.

WhatsApp: +8618764293079

Email: mwinbelt@qdmwingroup.com

Product Description

Rubber Vulcanizing Press Machine

A flat vulcanizing press, also commonly known as a slab vulcanizer, platen press, or compression molding press, is a fundamental and widely used machine in the rubber and plastics industries for the curing (vulcanization) and molding of materials. Its primary function is to apply precise heat and pressure to raw rubber compounds or other thermosetting polymers, transforming them into durable, elastic, and final-shaped products.

Core Components and Working Principle:

1. Frame: A robust structure, typically C-frame or four-column type, that houses the press and withstands the high operating forces.

2. Platens: These are the essential heavy, flat, heated steel plates—usually a fixed bottom platen and a movable top platen. They are heated by electric heaters, steam, or hot oil circulating through internal channels.

3. Hydraulic System: A hydraulic cylinder (or multiple cylinders) provides the powerful force required to close the press and apply high pressure (ranging from tens to hundreds of bar) on the material placed between the platens. This ensures the material fills the mold cavity completely and compacts it.

4. Control System: Modern presses feature programmable logic controllers (PLCs) and touch-screen interfaces. This allows operators to set and precisely control critical parameters: temperature (typically 140°C – 200°C for rubber), pressure, and cure time—the three essential elements for proper vulcanization.

5. Mold: The mold, containing the cavity for the desired product shape, is placed between the platens. The raw compound is loaded into this mold.

Basic Operation Cycle:

– Loading: The mold, filled with uncured rubber, is placed on the bottom platen.

– Closing & Pressurizing: The press closes, bringing the platens together and applying high pressure.

– Curing: Under maintained heat and pressure, the material undergoes the vulcanization chemical reaction, acquiring its final properties.

– Opening & Ejection: After the preset cure time, the press opens, and the finished, cured product is removed from the mold.

Key Applications:

– Manufacturing rubber sheets, gaskets, seals, and mats.

– Producing conveyor belt splices and repairs.

– Molding technical rubber products like O-rings, diaphragms, and shock absorbers.

– Curing silicone rubber products.

– Processing fiber-reinforced composite sheets and thermoset plastics (e.g., Bakelite).

Advantages:

– Versatility: Suitable for a vast range of products, from simple slabs to complex molded items.

– Precision & Consistency: Ensures uniform cure and consistent product quality through precise control.

– High Pressure Capability: Ideal for molding dense rubber compounds and composites.

– Reliability: Robust design with a relatively simple operational principle ensures long service life.

In summary, the flat vulcanizing press is a cornerstone piece of equipment for transforming raw, plastic polymers into strong, resilient, and functional vulcanized rubber or plastic components through the controlled application of heat and pressure. Its efficiency, control, and adaptability make it indispensable in polymer processing factories worldwide.

Product Specifications

| Model | XLB-50T | XLB-100T | XLB-150T | XLB-200T | XLB-250T | XLB-300T | XLB-350T | XLB-500T |

| Clamping force | 50T | 100T | 150T | 200T | 250T | 300T | 350T | 500T |

| Max system pressure | 21Mpa | 21Mpa | 21Mpa | 21Mpa | 21Mpa | 21Mpa | 21Mpa | 21Mpa |

| Stroke | 250mm | 250mm | 300mm | 300mm | 300mm | 300mm | 300mm | 300mm |

| Rapid clamping speed | 60mm/s | 60mm/s | 60mm/s | 60mm/s | 60mm/s | 60mm/s | 60mm/s | 60mm/s |

| Plate size | 380*380mm 400*400mm |

400*400mm 450*450mm 500*500mm |

500*500mm | 510*540mm 600*550mm |

650*650mm | 600*600mm 700*700mm |

700*700mm | 800*800mm 1000*850mm |

| Daylight | 350mm | 350mm | 350mm | 350mm | 350mm | 350mm | 350mm | 350mm |

| Working layer | Customized | Customized | Customized | Customized | Customized | Customized | Customized | Customized |

| Max temperature | 300C | 300C | 300C | 300C | 300C | 300C | 300C | 300C |

| Motor | 3 kw | 4kw | 5kw | 7.5kw | 7.5kw | 7.5 kw | 11kw | 13 kw |

| Control | PLC+HIM | PLC+HIM | PLC+HIM | PLC+HIM | PLC+HIM | PLC+HIM | PLC+HIM | PLC+HIM |

Tell Us What You're Looking For.

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!

More Product

Tell Us What You're Looking For.

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!