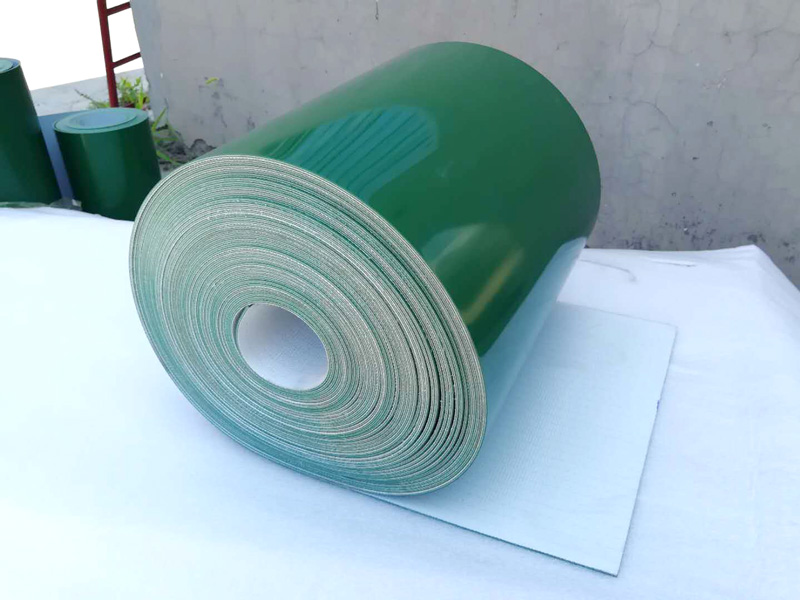

PVC Light Duty Food Grade Belt

PVC Light Duty Food Grade Belt

PVC (Polyvinyl Chloride) and PU (Polyurethane) belts are two of the most widely used types of lightweight synthetic conveyor belts across diverse industries. They offer a versatile, cost-effective, and durable solution for transporting a vast array of products.

WhatsApp: +8618764293079

Email: mwinbelt@qdmwingroup.com

Product Description

PVC Light Duty Food Grade Belt

PVC/PU Conveyor Belts: An Overview

PVC (Polyvinyl Chloride) and PU (Polyurethane) belts are two of the most widely used types of lightweight synthetic conveyor belts across diverse industries. They offer a versatile, cost-effective, and durable solution for transporting a vast array of products.

Core Composition:

PVC Belts: Made from polyester or nylon fabric plies coated with a polyvinyl chloride (PVC) compound. The PVC coating provides the belt’s key properties.

PU Belts: Made from polyester or nylon fabric plies coated with polyurethane (PU) elastomer. The PU coating is known for its exceptional flexibility, abrasion resistance, and cleanliness.

ommon Advantages of PVC & PU Belts:

Lightweight & Energy Efficient: Reduce power consumption on conveyor systems.

Customizable: Available in various thicknesses, ply constructions, colors, and surface textures (smooth, cleated, profiled, grip).

Easy to Clean & Maintain: Non-porous surfaces allow for easy washing and sanitization, crucial for food and pharmaceutical uses.

Seamless & Endless Splices: Can be made with welded, endless constructions for smooth operation and minimal contamination risk.

Good Mechanical Strength: The fabric carcass provides excellent tensile strength and dimensional stability.

Applications:

These belts are fundamental in:

Food & Beverage: Processing, packaging, inspection, washing.

Logistics & Parcel: Sorting, scanning, and transporting packages.

Manufacturing: Assembly lines, part feeding, and material handling.

Agriculture: Product sorting, washing, and grading.

General Industry: As a reliable and versatile conveying solution for non-heavy-duty loads.

In summary, PVC belts are the versatile, economical workhorses for general-purpose conveying, while PU belts are the premium choice for demanding applications requiring superior flexibility, abrasion resistance, cleanliness, and oil resistance. The selection depends on the specific material being conveyed, environmental conditions, and industry regulations.

Product Specifications

| Feature | PVC Belt | PU Belt |

| Primary Material | Polyvinyl Chloride | Polyurethane |

| Key Characteristics | Good durability, cost-effective, water-resistant, wide range of colors/patterns. | Excellent abrasion & cut resistance, high flexibility, oil/grease resistant, FDA-approved options available. |

| Surface Texture | Can vary from smooth to highly textured (e.g., cleated, rough top). | Often very smooth and non-porous, also available in textured versions. |

| Operating Temp. | Moderate range (approx. -10°C to +80°C). | Slightly wider range than PVC, but can degrade at very high temps. |

| Flexibility | Stiff to moderately flexible, depending on ply count. | Highly flexible, even at low temperatures; excellent for small pulley drives. |

| Chemical Resistance | Good resistance to water, acids, alkalis. | Superior resistance to oils, greases, and many solvents. |

| Typical Applications | Package handling, light assembly, agriculture, baggage handling, general conveying. | Food processing (slicing, washing, packaging), precision manufacturing, timber, recycling, steep incline conveying. |

Tell Us What You're Looking For.

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!

Tell Us What You're Looking For.

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!