Dip-Angle Corrugated Sidewall Conveyor Belt

Dip-Angle Corrugated Sidewall Conveyor Belt

A High-Angle Corrugated Sidewall Conveyor Belt is a specialized conveying system designed to transport bulk materials at steep inclines or even vertically, overcoming the limitations of traditional flat conveyor belts which are typically limited to inclines below 20 degrees.

WhatsApp: +8618764293079

Email: mwinbelt@qdmwingroup.com

Product Description

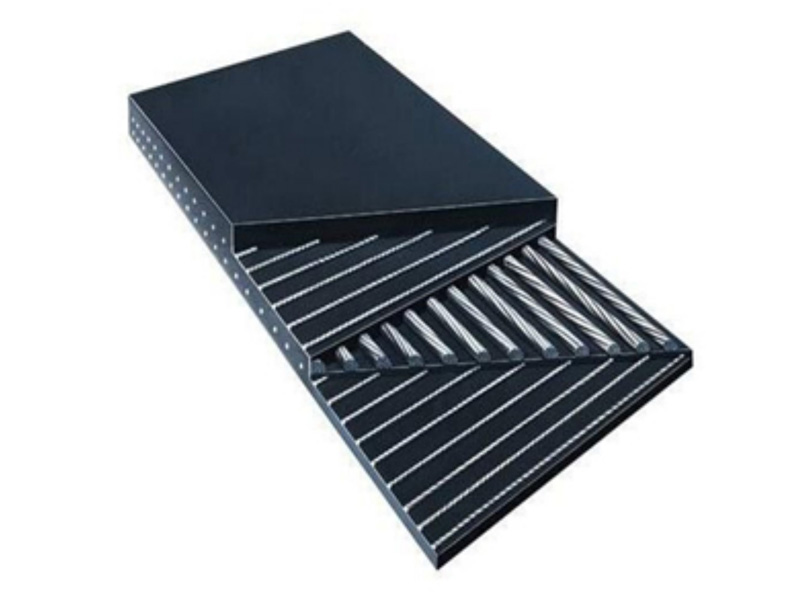

Dip-Angle Corrugated Sidewall Conveyor Belt

Core Features

1. Corrugated Sidewalls: The most distinctive feature is the vertical, corrugated (wave-shaped) rubber walls vulcanized onto both edges of the base belt. These sidewalls effectively contain the material and prevent it from rolling or sliding off the sides during high-angle ascent.

2. Cross Cleats (Bars): Flexible rubber cleats, spaced at regular intervals across the width of the belt, are vulcanized between the sidewalls. They form a series of closed compartments or “pockets” that securely hold the material in place, preventing backflow.

3. High-Strength Base Belt: The foundation is a robust fabric-reinforced (e.g., EP, NN) or steel cord reinforced belt, providing the necessary tensile strength to carry the loaded material and withstand the system’s drive forces.

4. Flexibility: Despite its strength, the belt system remains flexible enough to travel over standard conveyor pulleys at the head and tail ends.

Working Principle

The combination of corrugated sidewalls and cross cleats creates a continuous array of sealed cells. As the belt moves, these cells lift the material from the loading point at the bottom, carry it securely up the steep incline (capable of angles from 30° up to 90°), and discharge it at the top as the belt traverses the head pulley, where the cleats flatten out and the sidewalls flex.

Key Advantages

Space Efficiency: Drastically reduces the required floor space for material elevation compared to low-incline conveyors or mechanical lift systems.

High Capacity: Enables continuous vertical lifting of large volumes of bulk materials.

Versatility: Can handle a wide range of materials, from fine powders and granules to lumpy items (e.g., coal, ore, grain, crushed rock).

Single-Line Transport: Eliminates the need for multiple transfer points between conveyors, reducing dust, spillage, and equipment wear.

Cost-Effective: Often offers lower operational and maintenance costs compared to alternative systems like bucket elevators or multiple conveyor transfers.

Common Applications

Mining & Quarrying: Elevating mined minerals, coal, and aggregates.

Power Plants: Transporting fuel (coal, biomass) to bunkers.

Ports & Terminals: Ship loading/unloading and stockyard operations.

Chemical & Fertilizer Industry: Handling powders and granules.

Agriculture: Vertical transport of grains and feed.

In summary, the high-angle corrugated sidewall conveyor belt is an efficient, reliable, and space-saving solution for steep and vertical conveying challenges across numerous industries.

Product Specifications

Base Belt Specification

| Belt Type | Fabric type | Fabric Thickness | Rubber Cover Thickness | Width (mm) | Length (M) | |

| Top(mm) | Bottom(mm) | |||||

| EP Belt | EP-100 | 0.75 | 2-8 | 0-5 | 400-2500 | <=300 |

| EP-150 | 0.85 | |||||

| EP-200 | 0.90 | 500-2500 | ||||

| EP-250 | 1.15 | |||||

| EP-300 | 1.25 | |||||

| EP-400 | 1.45 | 600-2500 | ||||

| EP-500 | 1.55 | |||||

Producing Standard

| Rubber Cover Grade | Tensile Strength (Mpa) | Elongation at break (%) | Abrasion (mm3) |

| H | 24.0 | 450 | 120 |

| D | 18.0 | 400 | 100 |

| L | 15.0 | 350 | 200 |

| Standards | Cover Rubber | Adhesion | ||||

| Tensile Strength | Elongation at break | Abrasion | Cover to Ply | Cover to Ply | Ply to Ply | |

| DIN22102 | Mpa | % | mm3 | N/mm (≤1.5mm) |

N/mm (>1.5mm) |

N/mm |

| DIN 22102-Z | 15 | 350 | 250 | 3.5 | 4.5 | 5 |

| DIN 22102-W | 18 | 400 | 90 | 3.5 | 4.5 | 5 |

| DIN 22102-Y | 20 | 400 | 150 | 3.5 | 4.5 | 5 |

| DIN 22102-X | 25 | 450 | 120 | 3.5 | 4.5 | 5 |

| Standards | Cover Rubber | Adhesion | ||||

| Tensile Strength | Elongation at break | Abrasion | Cover to Ply | Cover to Ply | Ply to Ply | |

| AS 1332 | Mpa | % | mm3 | N/mm (≤1.9mm) |

N/mm (>1.9mm) |

N/mm |

| AS 1332-N17 | 17 | 400 | 200 | 4 | 4.8 | 6 |

| AS 1332-M24 | 24 | 450 | 125 | 4 | 4.8 | 6 |

We also could offer belt with cover grade in accordance to International standard such as DIN 22102, RMA, AS 1332, SABS 1173/2000, IS 1891, BS 490, JIS K 6322, etc.

Belt Sidewall and Cleat Type

| Cleat (mm) Sidewall (mm) | N | S | ES | ||||||||||||||

| Sidewall Type | |||||||||||||||||

| Sidewall Height | 40 | 60 | 80 | 100 | 120 | 160 | 200 | 240 | 300 | 400 | 500 | 630 | |||||

| Cleat Structure |  |

||||||||||||||||

| Cleat Type | TC | ||||||||||||||||

| Cleat Height | 35 | 55 | 75 | 90 | 110 | 140 | 180 | 220 | 280 | 360 | 460 | 580 | |||||

| Cleat Structure |  |

||||||||||||||||

| Cleat Type | T | ||||||||||||||||

| Cleat Height | 35 | 55 | 75 | 90 | 110 | 140 | 180 | 220 | 280 | 360 | 460 | 580 | |||||

| Cleat Structure |  |

||||||||||||||||

| Cleat Type | C | ||||||||||||||||

| Cleat Height | 55 | 75 | 90 | 110 | 140 | 180 | 220 | 280 | 360 | 460 | 580 | ||||||

Tell Us What You're Looking For.

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!

Tell Us What You're Looking For.

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!