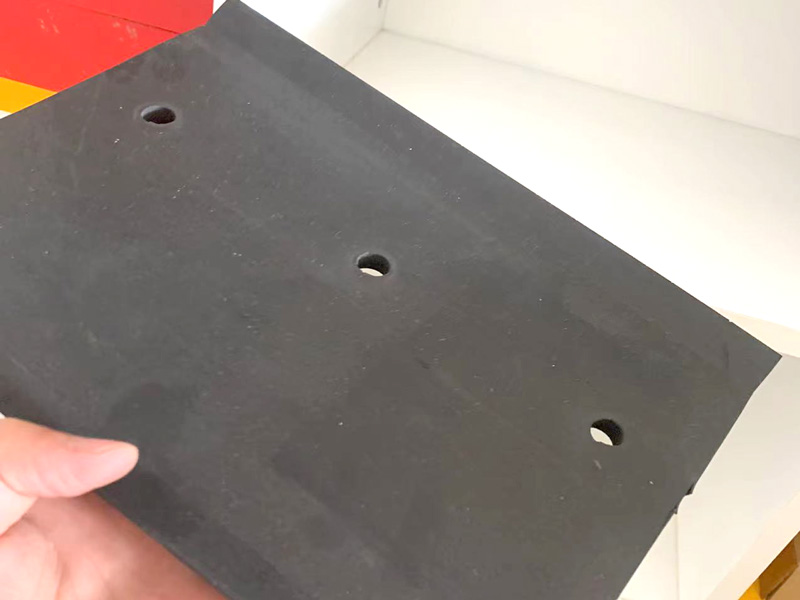

Rubber sheets

Rubber sheets

A rubber sheet is a versatile industrial material made by processing natural rubber, synthetic rubber (like SBR, NBR, EPDM, Neoprene, Silicone), or a blend of both. It is produced through mixing, calendering, or pressing raw rubber with additives (such as vulcanizing agents, fillers, and anti-aging agents) and then vulcanizing it into sheets of uniform thickness and specific properties.

WhatsApp: +8618764293079

Email: mwinbelt@qdmwingroup.com

Product Description

Rubber sheets

1. Definition and Basic Composition

A rubber sheet is a versatile industrial material made by processing natural rubber, synthetic rubber (like SBR, NBR, EPDM, Neoprene, Silicone), or a blend of both. It is produced through mixing, calendering, or pressing raw rubber with additives (such as vulcanizing agents, fillers, and anti-aging agents) and then vulcanizing it into sheets of uniform thickness and specific properties.

2. Key Characteristics and Properties

Rubber sheets are valued for their:

Elasticity and Flexibility: They can deform under pressure and return to their original shape.

Impermeability: Effective barrier against water, air, and certain gases/fluids.

Insulation: Good electrical, thermal, and sound insulation properties.

Resistance: Depending on the compound, they offer resistance to abrasion, impact, weathering, ozone, UV radiation, and a wide range of chemicals, oils, and temperatures.

Damping: Useful for vibration absorption and shock absorption.

3. Common Types and Their Primary Uses

Different base polymers create sheets for specific applications:

Natural Rubber (NR) Sheets: High elasticity and tensile strength. Used in gaskets, seals, and impact-absorbing pads.

Nitrile Rubber (NBR) Sheets: Excellent resistance to oils, fuels, and solvents. Common in automotive and machinery gaskets, fuel hoses.

Neoprene (CR) Sheets: Good weather, ozone, and moderate oil/fire resistance. Used in outdoor seals, weather stripping, and corrosion linings.

Ethylene Propylene Diene Monomer (EPDM) Sheets: Excellent weather, ozone, steam, and water resistance. Widely used in automotive weather seals, roofing membranes, and outdoor gaskets.

Silicone Rubber Sheets: High & low-temperature resistance (-60°C to 230°C), food/medical grade options, good electrical insulation. Used in food processing, medical devices, high-temperature gaskets, and insulation.

Fluorocarbon/Viton® (FKM) Sheets: Exceptional heat and chemical resistance. Used for demanding seals in aerospace, chemical, and automotive industries.

4. Main Applications Across Industries

Rubber sheets are critical components in:

Sealing and Gasketing: Creating static seals between flanges, covers, and housings in pipelines, machinery, and automotive assemblies.

Lining and Protection: Lining tanks, chutes, and hoppers in mining, chemical processing, and agriculture to protect against abrasion and corrosion.

Insulation: Serving as electrical insulation mats, thermal pads, and soundproofing layers in construction and electronics.

Flooring and Matting: Used for anti-fatigue mats, anti-slip surfaces, and vibration-damping pads in industrial and commercial settings.

Diaphragms and Membranes: Acting as flexible barriers in pumps, valves, regulators, and roofing systems.

Custom Fabrication: Cut, punched, or molded into specific parts like washers, seals, bushings, and rollers.

5. Standard Forms and Specifications

Rubber sheets are typically available in:

Rolls or Flat Sheets of standard width and length.

Various standard thicknesses (e.g., 1mm to 50mm or more).

Different hardness levels (measured in Shore A durometer, e.g., 40°A to 90°A).

Surface finishes: smooth, fabric-impressed, or textured.

May be reinforced with fabric or metal inserts for added strength.

6. Selection Considerations

Choosing the right rubber sheet involves evaluating:

Chemical/Medium Exposure: What fluids, oils, or solvents will it contact?

Temperature Range: Required operating minimum and maximum temperatures.

Pressure and Mechanical Stress: Load, compression, abrasion, or tearing forces.

Environmental Factors: Exposure to sunlight, ozone, oxygen, or weathering.

Regulatory Requirements: Need for FDA, NSF, UL, or other certifications.

Physical Properties: Required hardness, tensile strength, elongation, and elasticity.

In summary, rubber sheets are fundamental, adaptable engineering materials. Their specific compound determines their unique set of properties, making them essential for sealing, protecting, insulating, and damping in virtually every sector of modern industry, from manufacturing and automotive to construction and healthcare.

Tell Us What You're Looking For.

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!

Tell Us What You're Looking For.

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!