Roller Pulley Rubber Cover Lagging

Roller Pulley Rubber Cover Lagging

Roller lagging refers to the process of bonding a layer of rubber, or a rubber-like material, to the surface of industrial conveyor pulleys and rollers. Its primary purpose is to increase friction between the pulley and the conveyor belt, thereby improving traction and driving efficiency. It also protects the metal drum from wear, corrosion, and material buildup.

WhatsApp: +8618764293079

Email: mwinbelt@qdmwingroup.com

Product Description

Roller Pulley Rubber Cover Lagging

Introduction to Roller Lagging (Rubber Covering for Conveyor Pulleys)

Roller lagging refers to the process of bonding a layer of rubber, or a rubber-like material, to the surface of industrial conveyor pulleys and rollers. Its primary purpose is to increase friction between the pulley and the conveyor belt, thereby improving traction and driving efficiency. It also protects the metal drum from wear, corrosion, and material buildup.

Key Purposes & Benefits:

1. Improved Traction/Belt Grip: Prevents belt slippage, especially in wet, muddy, or inclined conditions, ensuring consistent power transmission.

2. Reduced Wear: Acts as a sacrificial layer, protecting the expensive metal pulley from abrasion and prolonging its lifespan.

3. Self-Cleaning: Certain patterns help dislodge carried-over material (coal, ore, dust), preventing buildup and maintaining belt alignment.

4. Protects the Belt: Provides a cushioned interface, reducing wear on the belt’s underside.

5. Noise Reduction: Dampens operational noise compared to metal-on-metal contact.

Main Types of Lagging:

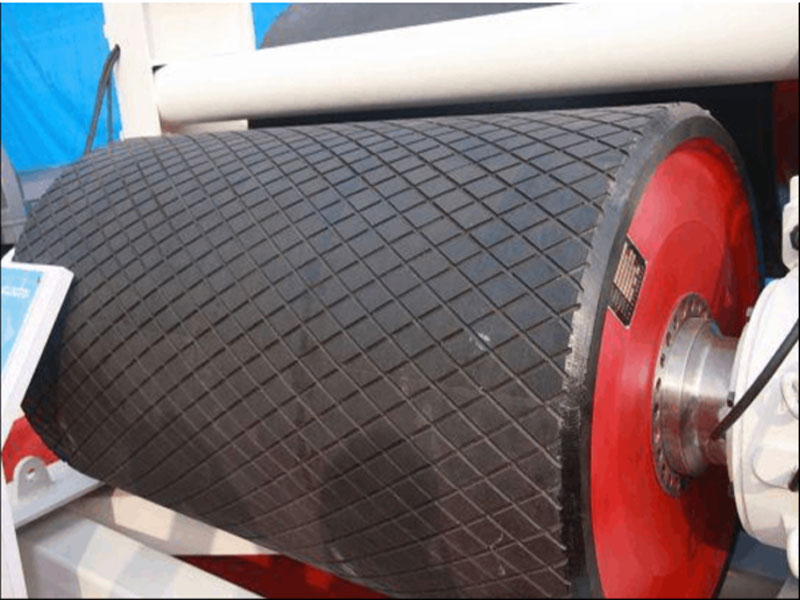

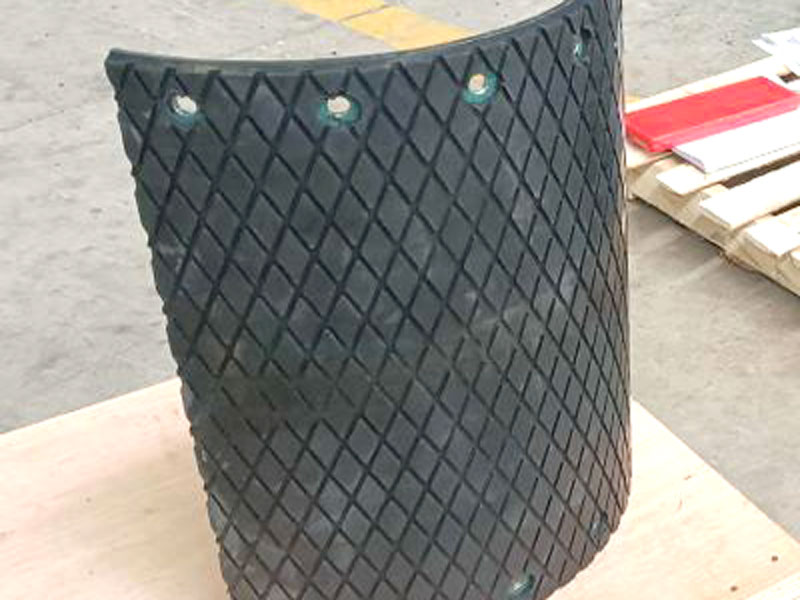

Description: Features a raised diamond or rhombus pattern. The most common and versatile type.

Advantages: Excellent all-around performance. The grooves provide multiple gripping edges and effectively channel away water, dust, and fine materials.

Applications: Standard drive pulleys, tail pulleys, and snub pulleys in most bulk handling environments (e.g., mining, aggregates, ports).

2. Herringbone Groove Lagging:

Description: Characterized by a V-shaped or chevron pattern that points toward the center of the pulley.

Advantages: Superior self-cleaning and water dispersal. The directional pattern “wipes” the belt and pushes debris outward, preventing misalignment.

Applications: Ideal for wet, sticky, or muddy conditions where material adhesion is a problem. Often used on tail and return pulleys.

Description: A smooth, non-patterned rubber surface.

Advantages: Easy to clean, provides uniform contact. Offers good grip in dry conditions.

Applications: Often used in food handling, packaging, or clean environments where material buildup must be minimized. Also used on non-drive rollers.

4. Ceramic Lagging:

Description: Rubber sheets with embedded, wear-resistant ceramic tiles or hexagons.

Advantages: Offers the highest possible friction coefficient (significantly higher than rubber alone). Extremely durable and abrasion-resistant.

Applications: Demanding, high-torque drive pulleys on long overland conveyors, steep inclines, or in applications where severe slippage is an issue.

Description: Made from polyurethane, a polymer known for high abrasion and tear resistance.

Advantages: Excellent resistance to oils, chemicals, and ozone. Performs well in a wide temperature range.

Applications: Specialized industries like wood processing, recycling, or chemical plants where oil or chemical resistance is required.

Installation Methods:

Bonded/Spliced Lagging: Rubber sheets are chemically bonded (vulcanized) to the pulley surface in a workshop. This provides a seamless, permanent, and high-performance installation.

Slide-On/Mechanical Lagging: Pre-fabricated rubber sleeves are stretched or slid onto the pulley and secured with end rings. Allows for faster replacement in the field without removing the pulley shaft.

Strip Lagging: Individual rubber strips are bolted or glued onto the pulley. Useful for repair and maintenance in the field.

Selection Considerations:

Choosing the right lagging depends on:

Pulley Function: Drive, tail, bend, or snub pulley?

Environmental Conditions: Wet, dry, dusty, corrosive, extreme temperatures?

Belt Tension & Power Requirements: High-torque drives need higher friction lagging (e.g., ceramic).

Material Characteristics: Sticky, abrasive, oily?

Cost & Lifecycle: Balancing initial cost with maintenance frequency and total service life.

In summary, roller lagging is a critical component in conveyor systems that enhances efficiency, safety, and reliability. Selecting the appropriate type and specification is essential for optimizing performance and reducing long-term operating costs.

Tell Us What You're Looking For.

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!

Tell Us What You're Looking For.

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!