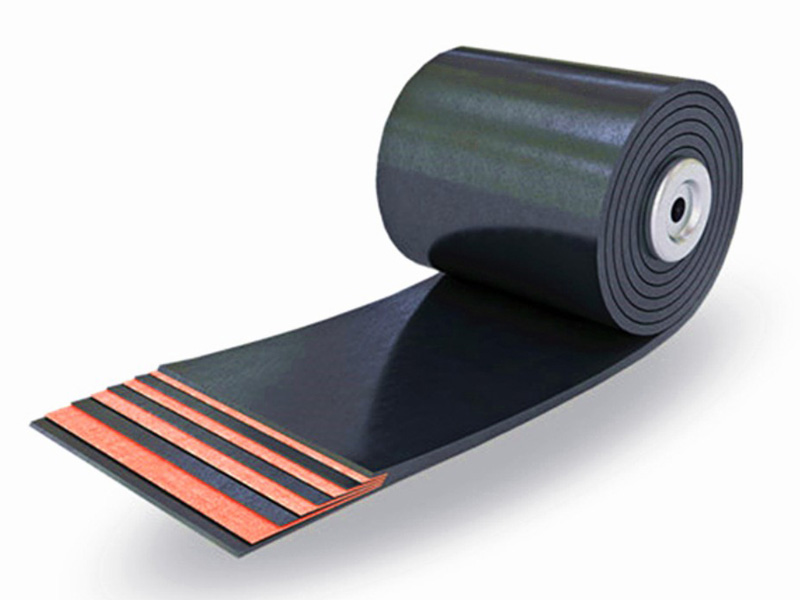

Heat-resistant conveyor belts

Heat-resistant conveyor belts

A heat-resistant conveyor belt is a specialized type of belting engineered to transport hot materials continuously in demanding industrial environments. Unlike standard belts, which can degrade, crack, or lose strength when exposed to high temperatures, these belts are constructed to maintain their structural integrity, operational safety, and longevity.

WhatsApp: +8618764293079

Email: mwinbelt@qdmwingroup.com

Product Description

Heat-resistant conveyor belts

A heat-resistant conveyor belt is a specialized type of belting engineered to transport hot materials continuously in demanding industrial environments. Unlike standard belts, which can degrade, crack, or lose strength when exposed to high temperatures, these belts are constructed to maintain their structural integrity, operational safety, and longevity.

Key Characteristics and Construction

1. Specialized Materials:

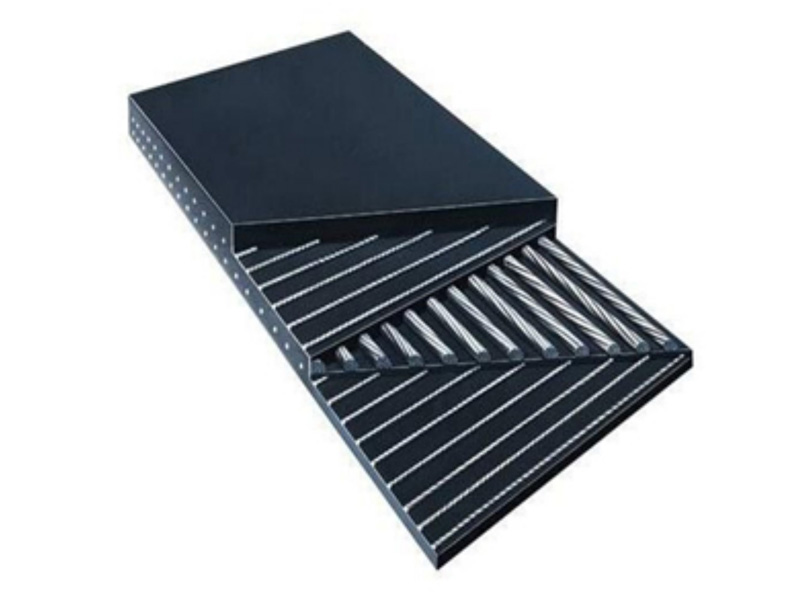

Carcass (Reinforcement): Typically made from high-tensile strength, heat-stabilized synthetic fabrics like EP (Polyester-Nylon) or, for extreme temperatures, steel cords. These materials are treated to resist thermal degradation.

Top & Bottom Cover: The most critical component. Made from compounded rubber formulations—often EPDM (Ethylene Propylene Diene Monomer) or SBR (Styrene-Butadiene Rubber) with specific additives. These compounds are designed to resist cracking, hardening, and abrasion caused by heat.

Insulating Layer: Many belts include a heat-insulating fabric or rubber layer between the carcass and the top cover to shield the tension-bearing carcass from the direct impact of heat.

2. Temperature Resistance:

* Belts are graded for specific temperature ranges. Common classifications include:

T1 (up to 100°C / 212°F): For moderately hot materials.

T2 (up to 125°C / 257°F): A common standard for many applications.

T3 (up to 150°C / 302°F): For high-temperature duties.

Specialized belts can handle short-term peaks up to 400°C – 600°C (752°F – 1112°F) for materials like sinter or coke.

* It’s crucial to distinguish between material temperature and ambient air temperature when selecting a belt.

Common Types and Applications

Heat-resistant belts are vital in industries where hot materials are processed:

Cement Industry: Transporting clinker (very hot), cement, and hot slag.

Steel & Metal Processing: Moving sinter, pellets, coke, castings, and steel coils.

Glass Manufacturing: Handling cullet (recycled glass) and hot finished products.

Foundries: For sand, castings, and debris.

Power Generation: Ash handling from coal-fired boilers.

Chemical and Fertilizer Plants: Moving hot chemical products.

Selection Considerations

Choosing the right belt involves evaluating:

Maximum and continuous operating temperature of the material.

Material Size and Abrasiveness: Sharp, heavy lumps cause more wear.

Load Impact: The force at the loading point.

Environmental Conditions: Exposure to moisture, oils, or chemicals in addition to heat.

System Tension and Pulley Diameters.

Advantages

Extended Service Life: Resists premature failure caused by heat.

Reduced Downtime: Minimizes unscheduled stops for belt replacement.

Improved Safety: Prevents sudden belt breaks that can cause accidents and fire hazards.

Cost-Efficiency: Higher initial cost is offset by lower long-term maintenance and replacement costs.

In summary, a heat-resistant conveyor belt is an essential engineered component that ensures reliable, safe, and efficient material handling in high-temperature industrial processes, protecting both the production flow and the investment in the conveyor system itself.

Product Specifications

1. Belt Specification:

| Belt Type | Fabric type | Fabric Thickness | Rubber Cover Thickness | Width (mm) | Length (M) | |

| Top(mm) | Bottom(mm) | |||||

| EP Belt | EP-100 | 0.75 | 2-8 | 0-5 | 400-2500 | <=300 |

| EP-150 | 0.85 | |||||

| EP-200 | 0.90 | 500-2500 | ||||

| EP-250 | 1.15 | |||||

| EP-300 | 1.25 | |||||

| EP-400 | 1.45 | 600-2500 | ||||

| EP-500 | 1.55 | |||||

| Belt Type | Fabric type | Fabric Thickness | Rubber Cover Thickness | Width (mm) | Length (M) | |

| Top(mm) | Bottom(mm) | |||||

| NN Belt | NN-100 | 0.75 | 2.5-8 | 0-5.5 | 400-2500 | <=300 |

| NN-150 | 0.8 | |||||

| NN-200 | 0.9 | 500-2500 | ||||

| NN-250 | 1.15 | |||||

| NN-300 | 1.25 | |||||

| NN-400 | 1.45 | 800-2500 | ||||

| NN-500 | 1.55 | |||||

2. Multiply Fabric Core Rubber Conveyor Belt Standard:

| Rubber Cover Grade | Tensile Strength (Mpa) | Elongation at break (%) | Abrasion (mm3) |

| H | 24.0 | 450 | 120 |

| D | 18.0 | 400 | 100 |

| L | 15.0 | 350 | 200 |

| Standards | Cover Rubber | Adhesion | ||||

| Tensile Strength | Elongation at break | Abrasion | Cover to Ply | Cover to Ply | Ply to Ply | |

| DIN22102 | Mpa | % | mm3 | N/mm (≤1.5mm) |

N/mm (>1.5mm) |

N/mm |

| DIN 22102-Z | 15 | 350 | 250 | 3.5 | 4.5 | 5 |

| DIN 22102-W | 18 | 400 | 90 | 3.5 | 4.5 | 5 |

| DIN 22102-Y | 20 | 400 | 150 | 3.5 | 4.5 | 5 |

| DIN 22102-X | 25 | 450 | 120 | 3.5 | 4.5 | 5 |

| Standards | Cover Rubber | Adhesion | ||||

| Tensile Strength | Elongation at break | Abrasion | Cover to Ply | Cover to Ply | Ply to Ply | |

| AS 1332 | Mpa | % | mm3 | N/mm (≤1.9mm) |

N/mm (>1.9mm) |

N/mm |

| AS 1332-N17 | 17 | 400 | 200 | 4 | 4.8 | 6 |

| AS 1332-M24 | 24 | 450 | 125 | 4 | 4.8 | 6 |

We also could offer belt with cover grade in accordance to International standard such as DIN 22102, RMA, AS 1332, SABS 1173/2000, IS 1891, BS 490, JIS K 6322, etc.

Tell Us What You're Looking For.

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!

Tell Us What You're Looking For.

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!