Conveyor Roller(Idler)

Conveyor Roller(Idler)

Conveyor idlers, often simply called rollers, are critical components of belt conveyor systems. They are cylindrical rollers mounted in a frame (idler frame) that support and guide the conveyor belt along its entire length, carrying the material load.

WhatsApp: +8618764293079

Email: mwinbelt@qdmwingroup.com

Product Description

Conveyor Roller(Idler)

Conveyor idlers, often simply called rollers, are critical components of belt conveyor systems. They are cylindrical rollers mounted in a frame (idler frame) that support and guide the conveyor belt along its entire length, carrying the material load.

Their primary function is to provide a stable, low-friction surface for the belt to travel on, minimizing belt sag, reducing wear and tear, and ensuring efficient material transport.

Key Types of Idlers:

1. Carrying Idlers:

Troughing Idlers: The most common type. Arranged in a “V” shape (usually 3 rollers: one horizontal center, two angled wing rollers) to create a trough. This shape helps contain bulk materials on the belt, increase load capacity, and prevent spillage.

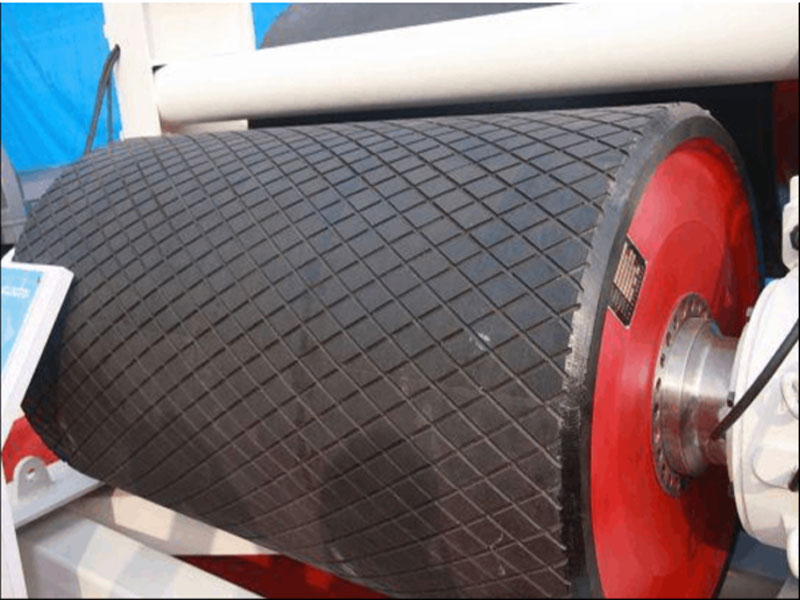

Impact Idlers: Located at loading points (e.g., under hoppers) where heavy or sharp materials fall onto the belt. They are equipped with rubber discs or rings to absorb impact energy and protect both the belt and the idler.

Return Idlers / Training Idlers: Support the empty return side of the belt. Flat return idlers are common. Some are designed as “training idlers,” which can pivot to automatically correct minor belt misalignment.

Garland Idlers: A series of short idlers connected by chains or links, forming a flexible multi-pivot suspension. Excellent for handling uneven loads and rough terrain, common in mining.

Spiral Idlers: Feature a continuous spiral wrapping around the roller body. They are excellent for cleaning sticky material from the belt’s return side and for use in wet conditions.

Rubber Disc Return Idlers: Similar to spiral idlers but use separate rubber discs. They prevent material buildup on the return roller, a major cause of belt mistracking.

Main Components & Design Features:

Shell/Tube: Usually made of steel (painted or galvanized), stainless steel, or plastic (HDPE) for corrosion resistance.

Bearings: Sealed, lubricated ball bearings are standard. Bearing selection (e.g., C3 clearance) and quality are crucial for longevity, especially in harsh environments.

Shaft: A solid steel shaft runs through the center, fixed to the idler frame.

Seals: High-quality labyrinth seals or multiple lip seals are essential to keep contaminants (dust, water, grit) out and grease in, dramatically extending bearing life. This is often rated by an IP (Ingress Protection) code.

Lubrication: Most modern idlers are pre-lubricated and sealed for life (“maintenance-free”). Some heavy-duty types have grease fittings for re-lubrication.

Applications:

Idlers are used in virtually every industry that employs belt conveyors:

- Mining (coal, ore, aggregates)

- Power Plants

- Cement and Steel Production

- Ports and Terminals (ship loading/unloading)

- Agriculture (grain handling)

- Packaging and Distribution Centers

Key Performance Factors:

- Sealing Effectiveness: The #1 factor for idler life in harsh conditions.

- Rotational Resistance: Lower starting and running force improves energy efficiency.

- Balance and Precision: Reduces vibration, belt wear, and noise.

- Durability: Resistance to corrosion, abrasion, and impact.

In summary, conveyor idlers are not just simple rollers; they are precision-engineered components whose design and condition directly determine the efficiency, reliability, and operating cost of a bulk material handling system.

Tell Us What You're Looking For.

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!

Tell Us What You're Looking For.

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!