Transmission Conveyor Belt V Belt

Transmission Conveyor Belt V Belt

A conveyor belt, more commonly known as a timing belt or positive drive belt, is a highly precise power transmission and conveying system. Unlike traditional friction-driven belts, it operates by meshing with pulleys that have matching teeth, ensuring no slippage between the belt and the pulley.

WhatsApp: +8618764293079

Email: mwinbelt@qdmwingroup.com

Product Description

Transmission Conveyor Belt V Belt

Introduction to Timing/Toothed/Transmission Conveyor Belts

A conveyor belt, more commonly known as a timing belt or positive drive belt, is a highly precise power transmission and conveying system. Unlike traditional friction-driven belts, it operates by meshing with pulleys that have matching teeth, ensuring no slippage between the belt and the pulley.

Core Principle & Design

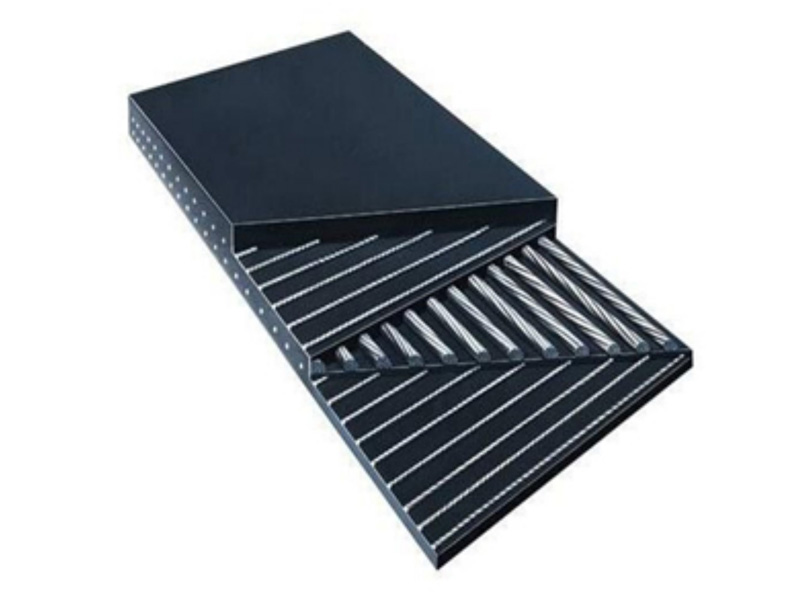

The key feature is the belt’s underside, which has evenly spaced teeth. These teeth engage with corresponding grooves on the pulleys (sprockets). This positive engagement guarantees that the input and output shafts rotate ly, maintaining a fixed speed ratio and precise positional alignment.

Key Components

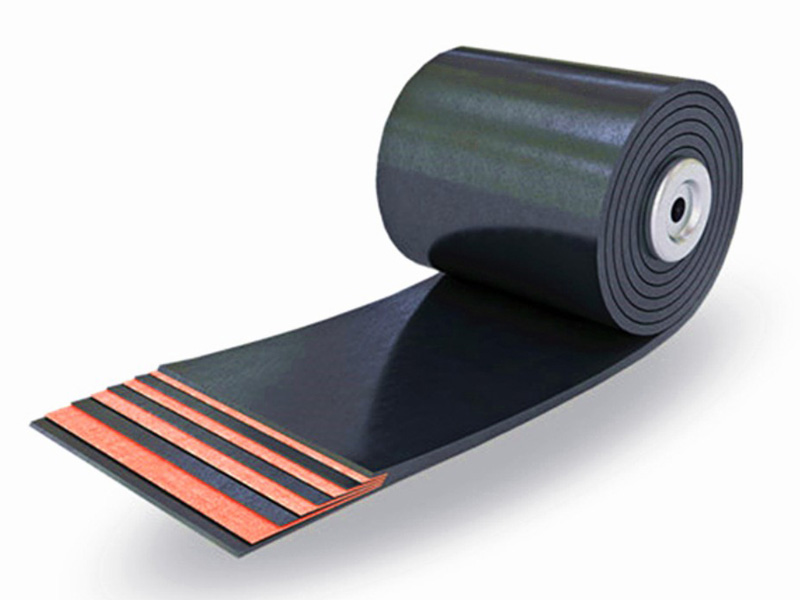

1. Belt Body: Made from durable materials like polyurethane (PU) or neoprene, often reinforced with high-tensile steel or aramid cords (like Kevlar) for strength and minimal stretch.

2. Teeth: The profile (shape and size) is critical. Common profiles include:

Trapezoidal (e.g., T10, XL): Classic design for general power transmission.

Curvilinear (e.g., HTD, GT): Rounded teeth for higher torque capacity and smoother engagement.

3. Pulleys (Sprockets): Precision-machined wheels with grooves that match the belt’s tooth profile. They are typically made from aluminum, steel, or plastic.

Primary Advantages

Zero Slip / Precise Synchronization: The most significant benefit. Essential for applications requiring exact positioning or phase alignment.

High Efficiency: Minimal energy loss compared to friction drives, as it doesn’t rely on tension for grip.

Low Maintenance: Requires less tension than V-belts, reducing bearing wear. No lubrication is needed (unlike chains).

Clean and Quiet Operation: Generates less noise and doesn’t shed debris like chain drives, making it suitable for clean environments.

High-Speed Capability: Can operate at significantly higher speeds than chain drives.

Compact Design: Capable of transmitting high power in a relatively small space.

Common Applications

conveyor belts are indispensable in industries where precision, timing, and repeatability are paramount:

Automation & Robotics: Moving parts between stations in assembly lines with exact positioning.

Packaging Machinery: Indexing products for filling, labeling, capping, or boxing.

Printing & Paper Processing: Precisely transporting sheets to maintain print registration.

Food & Pharmaceutical: Used in hygienic designs for portioning, sorting, and inspection (often made with FDA-approved materials).

3D Printers & CNC Machines: Providing accurate linear motion for the print head or tool.

Automotive: In engine camshaft drives (timing belts) and precision manufacturing lines.

Comparison with Alternative Systems

Vs. Flat/Friction Belts: Superior for positioning but generally has a lower total load capacity. Friction belts are better for absorbing shock loads.

Vs. Roller Chains: Quieter, cleaner, and requires no lubrication, but chains are typically stronger for extremely high-torque, heavy-duty applications.

Vs. V-Belts: More precise and efficient, but V-belts are simpler and often more cost-effective for non-critical power transmission.

In summary, the conveyor belt is the system of choice when the absolute synchronization of movement is required. Its ability to provide a reliable, clean, and maintenance-friendly positive drive makes it a cornerstone of modern precision automation and manufacturing.

Tell Us What You're Looking For.

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!

Tell Us What You're Looking For.

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!