EP/Nylon Fabric Rubber Conveyor Belts

EP/Nylon Fabric Rubber Conveyor Belts

EP fabric belts are a class of high-performance industrial conveyor belts and a cornerstone of modern bulk material handling systems. The name "EP" stands for E-Polyester, indicating the specific synthetic fabrics used in their construction.

WhatsApp: +8618764293079

Email: mwinbelt@qdmwingroup.com

Product Description

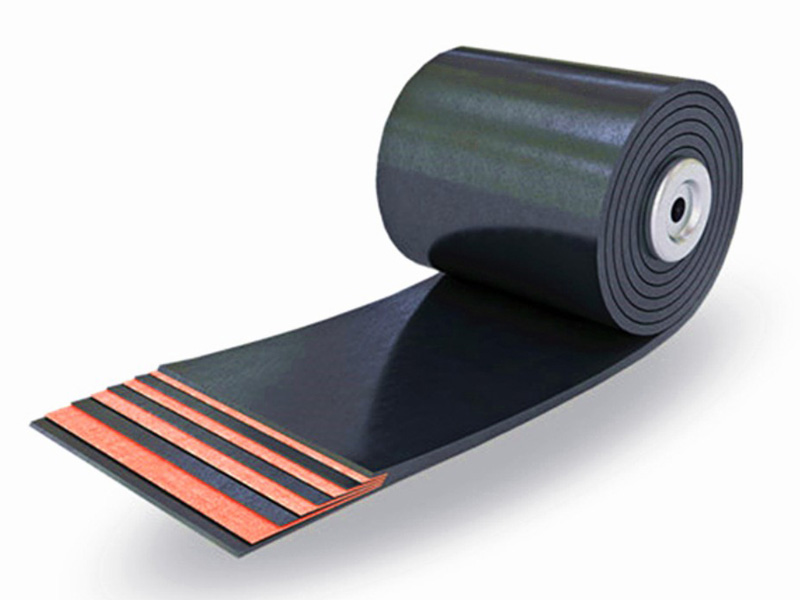

EP/Nylon Fabric Rubber Conveyor Belts

EP fabric belts are a class of high-performance industrial conveyor belts and a cornerstone of modern bulk material handling systems. The name “EP” stands for E-Polyester, indicating the specific synthetic fabrics used in their construction.

1. What Does “EP” Mean?

E: Stands for Polyester in the warp (longitudinal) direction. Polyester fibers provide exceptional tensile strength and low stretch, ensuring the belt maintains its length and does not elongate significantly under load.

P: Stands for Polyamide (Nylon) in the weft (cross) direction. Polyamide fibers offer excellent flexibility, impact resistance, and load support, allowing the belt to absorb shocks and form a good trough.

This combination creates a fabric that leverages the strengths of both synthetic materials.

2. Key Structure & Components

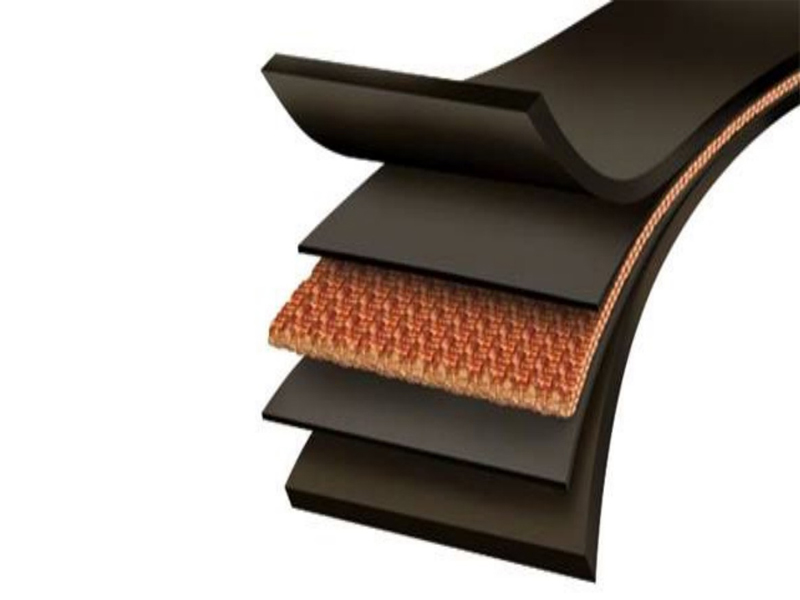

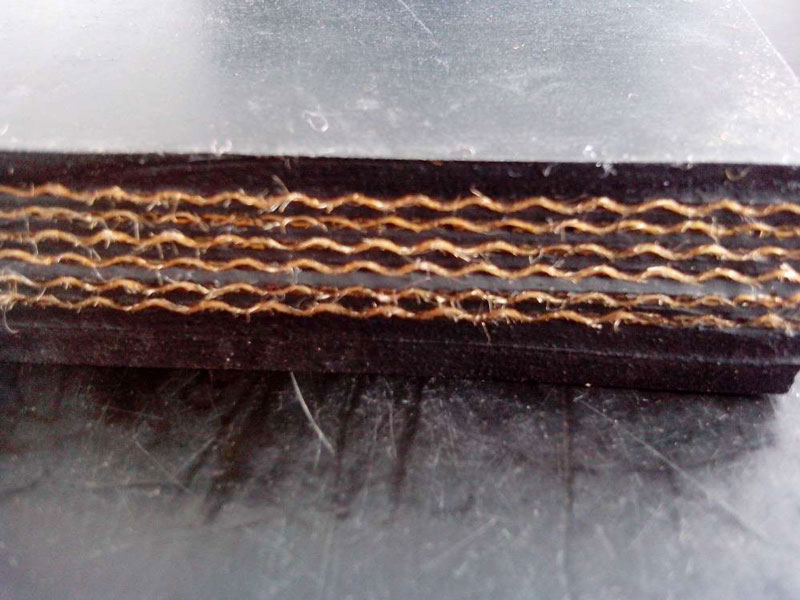

A typical EP conveyor belt is built in layers:

Carcass (Reinforcement): The heart of the belt, consisting of multiple plies (layers) of EP fabric bonded together. This provides the belt’s tensile strength and defines its flexibility and load-bearing capacity.

Covers (Top & Bottom): These are layers of rubber or PVC/PU compound that protect the carcass. The top cover handles wear, abrasion, and the impact of the material. The bottom cover protects against friction from idlers and pulleys.

Skim Coat: A thin layer of rubber between each fabric ply to ensure proper adhesion and flexibility.

3. Primary Characteristics & Advantages

High Strength with Low Elongation: The polyester warp gives EP belts a much lower permanent elongation (typically 1-2%) compared to all-nylon (NN) belts. This reduces the need for frequent take-up adjustments and saves energy.

Excellent Dimensional Stability: They are less susceptible to moisture and humidity than cotton or nylon fabrics, maintaining consistent length and performance in varying environments.

Good Impact & Tear Resistance: The polyamide weft provides excellent toughness for absorbing the shock of loaded material.

Flexibility & Troughability: EP fabric allows for good troughing, which helps contain the load and increase carrying capacity.

Rot Resistance & Mildew Resistance: Synthetic fibers are immune to rot, mildew, and biological degradation, making them suitable for a wide range of environments.

4. Common Applications

EP belts are versatile and used across numerous industries for transporting bulk materials like:

Mining (coal, ore, aggregates)

Quarrying and cement production

Port and ship loading/unloading

Power plants

Agriculture (grain, fertilizer)

Packaging and distribution centers

5. Selection Parameters

When specifying an EP belt, key parameters include:

EP Grade: e.g., EP100, EP200, EP300, etc. The number indicates the fabric’s tensile strength in N/mm per ply.

Number of Plies: Determines the total belt strength.

Cover Thickness & Grade: Chosen based on the abrasiveness and impact of the material (e.g., standard, abrasion-resistant, heat-resistant, oil-resistant compounds).

Belt Width and Length.

Conclusion

In summary, EP fabric belts offer an optimal balance of strength, low stretch, durability, and cost-effectiveness, making them the most widely used type of synthetic conveyor belt for general and heavy-duty bulk material handling worldwide. Their robust construction from polyester and polyamide fabrics ensures reliable performance under demanding conditions.

Product Specifications

1. Belt Specification:

| Belt Type | Fabric type | Fabric Thickness | Rubber Cover Thickness | Width (mm) | Length (M) | |

| Top(mm) | Bottom(mm) | |||||

| EP Belt | EP-100 | 0.75 | 2-8 | 0-5 | 400-2500 | <=300 |

| EP-150 | 0.85 | |||||

| EP-200 | 0.90 | 500-2500 | ||||

| EP-250 | 1.15 | |||||

| EP-300 | 1.25 | |||||

| EP-400 | 1.45 | 600-2500 | ||||

| EP-500 | 1.55 | |||||

| Belt Type | Fabric type | Fabric Thickness | Rubber Cover Thickness | Width (mm) | Length (M) | |

| Top(mm) | Bottom(mm) | |||||

| NN Belt | NN-100 | 0.75 | 2.5-8 | 0-5.5 | 400-2500 | <=300 |

| NN-150 | 0.8 | |||||

| NN-200 | 0.9 | 500-2500 | ||||

| NN-250 | 1.15 | |||||

| NN-300 | 1.25 | |||||

| NN-400 | 1.45 | 800-2500 | ||||

| NN-500 | 1.55 | |||||

2. Produce Standard:

| Rubber Cover Grade | Tensile Strength (Mpa) | Elongation at break (%) | Abrasion (mm3) |

| H | 24.0 | 450 | 120 |

| D | 18.0 | 400 | 100 |

| L | 15.0 | 350 | 200 |

| Standards | Cover Rubber | Adhesion | ||||

| Tensile Strength | Elongation at break | Abrasion | Cover to Ply | Cover to Ply | Ply to Ply | |

| DIN22102 | Mpa | % | mm3 | N/mm (≤1.5mm) |

N/mm (>1.5mm) |

N/mm |

| DIN 22102-Z | 15 | 350 | 250 | 3.5 | 4.5 | 5 |

| DIN 22102-W | 18 | 400 | 90 | 3.5 | 4.5 | 5 |

| DIN 22102-Y | 20 | 400 | 150 | 3.5 | 4.5 | 5 |

| DIN 22102-X | 25 | 450 | 120 | 3.5 | 4.5 | 5 |

| Standards | Cover Rubber | Adhesion | ||||

| Tensile Strength | Elongation at break | Abrasion | Cover to Ply | Cover to Ply | Ply to Ply | |

| AS 1332 | Mpa | % | mm3 | N/mm (≤1.9mm) |

N/mm (>1.9mm) |

N/mm |

| AS 1332-N17 | 17 | 400 | 200 | 4 | 4.8 | 6 |

| AS 1332-M24 | 24 | 450 | 125 | 4 | 4.8 | 6 |

We also could offer belt with cover grade in accordance to International standard such as DIN 22102, RMA, AS 1332, SABS 1173/2000, IS 1891, BS 490, JIS K 6322, etc.

Tell Us What You're Looking For.

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!

Tell Us What You're Looking For.

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!