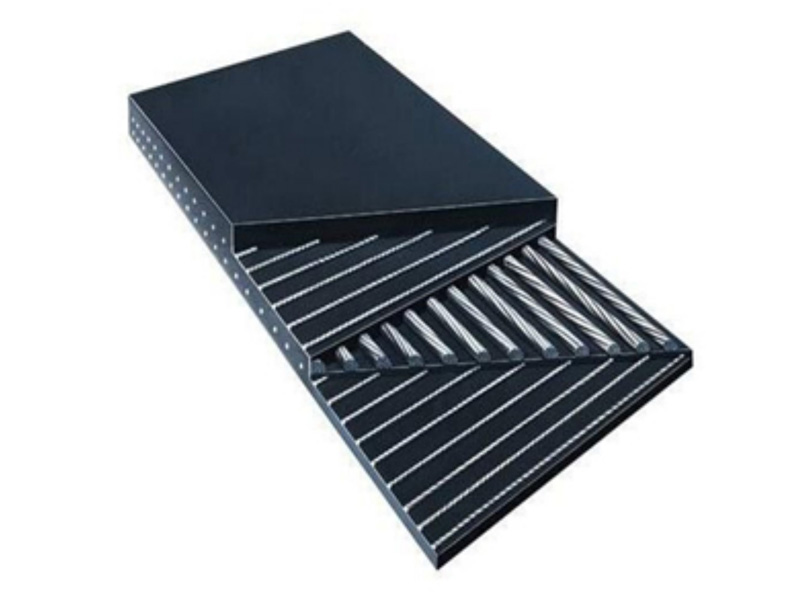

Steel Cord Rubber Conveyor Belt

Steel Cord Rubber Conveyor Belt

A steel cord rubber conveyor belt is a high-performance, heavy-duty conveyor belt designed for long-distance, high-tension, and large-capacity material handling applications. Its core distinguishing feature is the use of steel cables as the primary tensile member, unlike traditional belts that use fabric plies (like polyester or nylon).

WhatsApp: +8618764293079

Email: mwinbelt@qdmwingroup.com

Product Description

Steel Cord Rubber Conveyor Belt

A steel cord rubber conveyor belt is a high-performance, heavy-duty conveyor belt designed for long-distance, high-tension, and large-capacity material handling applications. Its core distinguishing feature is the use of steel cables as the primary tensile member, unlike traditional belts that use fabric plies (like polyester or nylon).

Here is a breakdown of its key aspects:

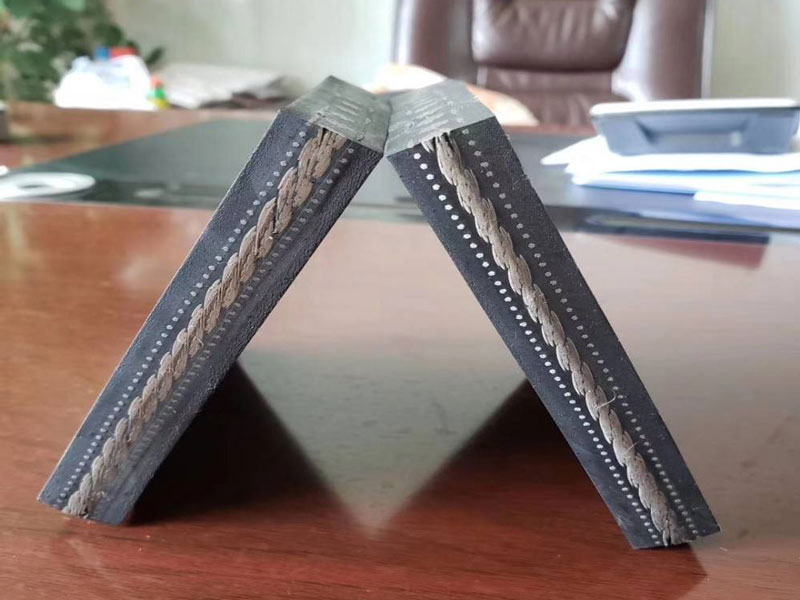

1. Core Structure & Composition:

- · Top & Bottom Cover: Made of wear-resistant, cut-resistant, and often weather or fire-resistant rubber compounds. The top cover protects the core from the load and impact, while the bottom cover protects it from friction with conveyor components.

- · Steel Cord Reinforcement: This is the heart of the belt. High-carbon steel wires are twisted into strands, which are then laid side-by-side across the entire belt width. These cords are embedded in a special rubber skim coat that provides excellent adhesion, flexibility, and corrosion protection.

- · Edge Protection: The edges are often reinforced or sealed to prevent moisture ingress and cord damage.

2. Key Characteristics & Advantages:

- · Extremely High Tensile Strength: The steel cords provide exceptional strength, allowing the belt to handle very long single-span distances (often over several kilometers) without intermediate drives.

- · Low Elongation: Minimal stretch under load ensures consistent tracking and efficient power transmission from the drive pulley.

- · Excellent Impact & Tear Resistance: Suitable for heavy and sharp materials like large rocks and ores.

- · Good Flexibility & Fatigue Resistance: Despite the steel core, the belt design allows it to trough over idlers and bend around pulleys reliably.

- · Long Service Life: Designed for durability in the most demanding conditions, such as mining and bulk shipping.

- · Good Rip Propagation Resistance: The longitudinal orientation of the cords helps localize longitudinal rips.

3. Primary Applications:

This belt type is essential in industries requiring robust and reliable high-capacity transport:

- · Mining: Main haulage lines in surface and underground mines for coal, metal ores, and overburden.

- · Ports & Terminals: Ship loading and unloading of bulk materials like grains, coal, and minerals.

- · Large-Scale Quarrying & Cement Plants: Transporting limestone, aggregates, and clinker.

- · Long-Distance Overland Conveying: Moving materials from a mine or quarry directly to a processing plant or railhead over many kilometers.

In summary, the steel cord rubber conveyor belt is the backbone of heavy-industry material transport, offering unmatched strength, durability, and efficiency for the most demanding conveying tasks. Its design represents the optimal solution where high tension and long distances are the primary challenges.

Product Specifications

1. Steel Cord Rubber Conveyor Belt Specification:

| Strength Technical Data | Tensile Strength (N/mm) | Steel Cord Diameter (mm) | Steel Cord Pitch(mm) | Top Cover (mm) | Bottom cover(mm) | Weight (Kg/M) |

| ST630 | 630 | 3.0 | 10 | 5 | 5 | 18 |

| ST800 | 800 | 3.5 | 10 | 5 | 5 | 19.5 |

| ST1000 | 1000 | 4.0 | 12 | 6 | 5 | 22.4 |

| ST1250 | 1250 | 4.5 | 12 | 6 | 6 | 24 |

| ST1600 | 1600 | 5.0 | 12 | 6 | 6 | 25.9 |

| ST2000 | 2000 | 6.0 | 12 | 6 | 6 | 31.8 |

| ST2500 | 2500 | 7.2 | 15 | 6 | 6 | 36.1 |

| ST3150 | 3150 | 8.1 | 15 | 8 | 8 | 40.4 |

| ST3500 | 3500 | 8.6 | 15 | 8 | 8 | 43.8 |

| ST4000 | 4000 | 8.9 | 15 | 8 | 8 | 45 |

| ST4500 | 4500 | 9.7 | 16 | 8.5 | 8.5 | 46.7 |

| ST5000 | 5000 | 10.9 | 17 | 9 | 9 | 50.7 |

Remark:

The above data is according to the GB/T5753-2008 Standard.

We also can produce the belt in according to customer’s request standard.

2. Production standards:

| Rubber Cover Grade | Tensile Strength (Mpa) | Elongation at break (%) | Abrasion (mm3) |

| H | 24.0 | 450 | 120 |

| D | 18.0 | 400 | 100 |

| L | 15.0 | 350 | 200 |

| Standards | Cover Rubber | Adhesion | ||||

| Tensile Strength | Elongation at break | Abrasion | Cover to Ply | Cover to Ply | Ply to Ply | |

| DIN22102 | Mpa | % | mm3 | N/mm (≤1.5mm) |

N/mm (>1.5mm) |

N/mm |

| DIN 22102-Z | 15 | 350 | 250 | 3.5 | 4.5 | 5 |

| DIN 22102-W | 18 | 400 | 90 | 3.5 | 4.5 | 5 |

| DIN 22102-Y | 20 | 400 | 150 | 3.5 | 4.5 | 5 |

| DIN 22102-X | 25 | 450 | 120 | 3.5 | 4.5 | 5 |

| Standards | Cover Rubber | Adhesion | ||||

| Tensile Strength | Elongation at break | Abrasion | Cover to Ply | Cover to Ply | Ply to Ply | |

| AS 1332 | Mpa | % | mm3 | N/mm (≤1.9mm) |

N/mm (>1.9mm) |

N/mm |

| AS 1332-N17 | 17 | 400 | 200 | 4 | 4.8 | 6 |

| AS 1332-M24 | 24 | 450 | 125 | 4 | 4.8 | 6 |

We also could offer belt with cover grade in accordance to International standard such as DIN 22102, RMA, AS 1332, SABS 1173/2000, IS 1891, BS 490, JIS K 6322, etc.

Tell Us What You're Looking For.

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!

Tell Us What You're Looking For.

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!