Corrugated Sidewall Conveyor Machine

Corrugated Sidewall Conveyor Machine

A Sidewall Belt Conveyor is a specialized and highly efficient bulk material handling system designed to move materials at steep inclines or even vertically. It overcomes the fundamental limitation of traditional flat conveyor belts, which are typically restricted to inclines below 20 degrees.

WhatsApp: +8618764293079

Email: mwinbelt@qdmwingroup.com

Product Description

Corrugated Sidewall Conveyor Machine

A Sidewall Belt Conveyor (also known as a Corrugated Sidewall Belt Conveyor, Flexowell Conveyor, or Vertical Conveyor) is a specialized and highly efficient bulk material handling system designed to move materials at steep inclines or even vertically. It overcomes the fundamental limitation of traditional flat conveyor belts, which are typically restricted to inclines below 20 degrees.

Core Concept

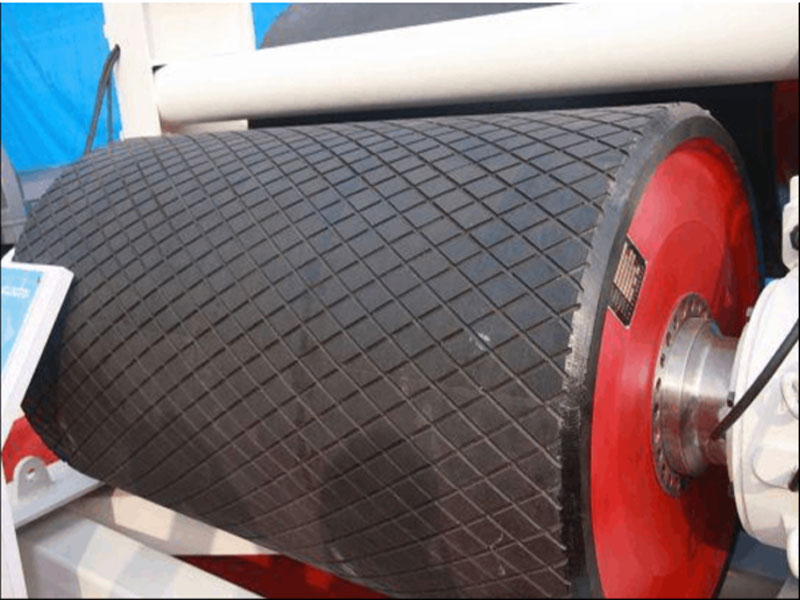

The system integrates a standard rubber conveyor belt with flexible, continuous corrugated sidewalls that are vulcanized onto the belt edges. Transverse cleats (or flights) are then attached at regular intervals between the sidewalls, creating a series of sealed pockets or compartments. These pockets securely contain the material, preventing rollback and spillage during high-angle transport.

Key Components & Design Features

1. Base Belt: The carcass provides the tensile strength. It is typically a rugged, flexible fabric or steel cord belt designed to handle the significant tension and flexing required for the system.

2. Corrugated Sidewalls: Made of specially formulated, flexible rubber, these vertical walls are the defining feature. They are molded into a corrugated (wave-like) pattern, which provides excellent rigidity to contain the load while maintaining the flexibility needed to travel over the conveyor’s pulleys.

3. Cleats (Flights): These are the cross bars that form the back of each pocket. Cleats are sized and spaced according to the material size and incline angle. They bear the direct load of the material and provide the positive thrust for lifting.

4. Specialized Pulleys and Idlers: The conveyor uses specially designed drives, bend pulleys, and idlers to accommodate the belt’s unique profile, ensuring smooth transition from horizontal feeding to vertical lifting and back to horizontal discharge.

Primary Advantages

Steep to Vertical Incline: The most significant benefit. It can convey materials at angles from 30 degrees up to 90 degrees (vertical), saving enormous amounts of floor space compared to long, low-angle conveyors or elevator systems.

Continuous, High-Capacity Flow: Unlike bucket elevators which operate intermittently, it provides a continuous, smooth material flow with high capacity in a single, compact unit.

Single-Belt System: Eliminates transfer points between a horizontal conveyor and an elevator, reducing dust, spillage, degradation of fragile material, and points of maintenance.

Material Versatility: Can handle a wide range of bulk materials: free-flowing granules (plastic pellets, grains), powders (cement, fly ash), lumps (coal, ore, crushed stone), and even abrasive or hot materials (with appropriate belt specifications).

Space Efficiency and Layout Flexibility: Ideal for confined spaces, existing plants, or applications where a straight-line path from intake to discharge point is needed over a significant elevation change.

Typical Applications

Mining & Quarrying: Transporting crushed ore, limestone, or aggregates from a lower pit or crusher to an elevated stockpile or processing plant.

Power Plants: Moving coal, biomass, or ash to bunkers or silos.

Cement Industry: Handling raw meal, clinker, and finished cement.

Chemical & Fertilizer Plants: Conveying granules, powders, and pellets.

Ports & Terminals: Loading/unloading ships or barges, and transferring material to storage.

Food & Grain Processing: Moving grains, sugar, or other food products where contained, clean handling is essential.

Configuration Types

L-Type: Features a horizontal feed section leading into the inclined section. Most common configuration.

S-Type: Has a horizontal tail, an inclined section, and a horizontal discharge section, forming an “S” shape. This provides a gentler transition and is better for very fragile materials.

Z-Type: Similar to S-type but with two vertical bends, allowing both loading and discharge at the same elevation but at different horizontal points.

Considerations

Capital Cost: Generally higher than a standard flat belt conveyor due to its specialized belt and components.

Belt Maintenance: The belt itself is more complex and expensive to replace. Proper alignment and tensioning are critical.

Material Limitations: Not suitable for very large, sharp-edged rocks or extremely sticky materials that may not discharge cleanly from the pockets.

In summary, the Sidewall Belt Conveyor is a robust, space-saving, and efficient solution for steep incline conveying, bridging the gap between traditional conveyors and vertical elevators.

Tell Us What You're Looking For.

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!

Tell Us What You're Looking For.

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!